Similar

Illustrated catalogue of cotton machinery built by Howard and Bullough American Machine Company, Ltd., Pawtucket, R.I., U.S.A. - opening, picking, carding, drawing, roving, spinning, twisting and (14596133109)

Summary

Identifier: illustratedcatal00howa (find matches)

Title: Illustrated catalogue of cotton machinery built by Howard & Bullough American Machine Company, Ltd., Pawtucket, R.I., U.S.A. : opening, picking, carding, drawing, roving, spinning, twisting and winding machinery : warpers and slashers : containing also floor spaces, speeds, productions, gearing diagrams, useful tables and other information

Year: 1909 (1900s)

Authors: Howard & Bullough American Machine Co

Subjects: Howard & Bullough American Machine Co Cotton machinery Cotton machinery Cotton machinery industry -- Rhode Island Pawtucket Textile machinery industry -- Rhode Island Pawtucket

Publisher: (Pawtucket, R.I. : Howard & Bullough American Machine Company)

Contributing Library: Claire T. Carney Library, University of Massachusetts Dartmouth

Digitizing Sponsor: Claire T. Carney Library, University of Massachusetts Dartmouth

Text Appearing Before Image:

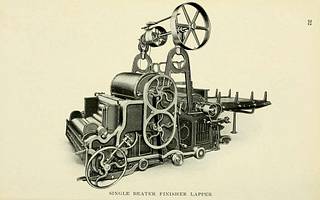

ination and, it will be noted, is builtas one straight machine. A floor plan and eleva-tion are shown on page 54. This same combina-tion with an 18-in. Beater instead of the 30-in.Cylinder in the Opener Section is shown in planand elevation on page 55. We also build a Self-feeding Opener with CageSection and Calender Head, which is well adaptedto work Egyptian and Sea Island cottons. (Seepage 53 for plan and elevation.) Self-feeding Openers when built as separatemachines can be placed on any floor above or belowthe Breaker Lappers, or on the same floor, the con-nections being made by Automatic Cleaning Trunks,Conducting Trunks, and galvanized iron pipe, asthe conditions may require. On pages 56 and 57 we show Single BeaterBreaker Lappers with Gauge Boxes and Condensersconnected to Self-feeding Openers by short sec-tions of Conducting Trunk. The Breakers are onthe floor above the Openers. One drawing showsthe Self-feeding Opener with 18-in. Beater, andthe other with 3U-in. Cylinder. 32

Text Appearing After Image:

33INTERMEDIATE AND FINISHER LAPPERS. These machines have our improved Calender Head,which has already been described in connection with BreakerLappers. Each machine has a countershaft and pulleys com-plete with stands as shown. BEATER BOXES—AH our beater boxes are fixed and ourfeed rolls adjustable, w^hich we consider superior to havingthe beaters adjustable. After thorough investigation andlong practice we have found that adjustable beaters are liableto get out of line, causing them to heat and wear quickly. DRAFT REGULATION—The air chamber from fan tocage section on each side of the machine is supplied witha damper, operated from the outside of the machine. Withthis arrangement the air can be drawn through the top andbottom cages in any desired proportion, and the operator canregulate the drafts to give the best results. BEATERS—Two-blade (18 in. dia.) beaters are mostlyused, but we furnish the Houghton patent beater with corru-gated teeth, or carding beaters, when specified.

Tags

Date

Source

Copyright info